• Transformadores usados com garantia

• Transformadores a seco e a óleo

• Limpeza geral

• Secagem em estufa

• Revisão geral

• Testes no relé de temperatura

• Testes nos sensores de temperatura

• Reparo de oxidação do núcleo

• Ensaios de rotina NBR 5356/11 (11 ensaios)

• Laudo - indicará se o transformador está apto ou não para energização

• Substituição das bobinas de baixa tensão

• Substituição da instrumentação (quando aplicável)

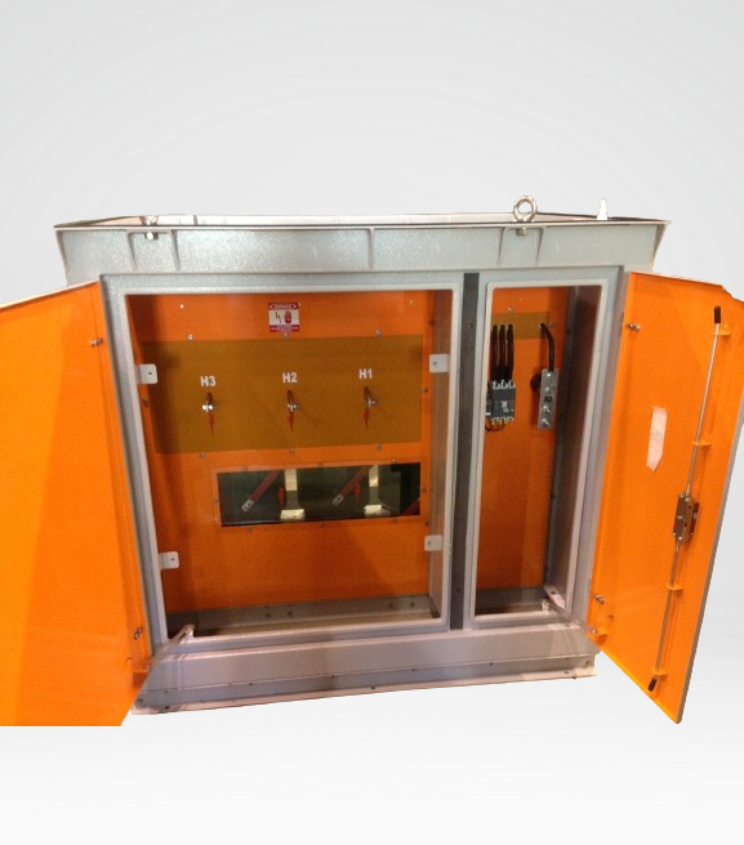

Main features:

Production Capacity:

Power up to 20MVA;

Voltage Classes: 7.2kV, 15kV, 24.2kV and 36.2kV;

Degree of Protection: IP 00 to IP 65;

Temperature class: B, F or H;

Vacuum “AT” coil encapsulation process, using epoxy resin;

Grain-oriented silicon core with “Step Lap” assembly;

Built and tested according to standards: ABNT, IEC or ANSI.

Benefits:

They are not affected by ambient humidity;

Eco-friendly, not causing any harm to the environment;

Provide savings in civil construction, as they do not require fire doors and wells to collect fluids;

Can be installed close to the load center, therefore reducing losses and voltage drops in low voltage cables;

No need for gas relays, level indicators, pressure gauges or pressure valves;

Practically maintenance-free.

Applications:

We create Dry-Type Medium Voltage transformers for the most diverse applications: Energy distribution for Industries, Malls, Condos, Residential Homes and Hospitals. Also for Naval, Mining, Metro and Railway use, Oil Production and Refining, Lighting, Grounding, Supply of loads with high Harmonic content (K Factor) and for use in Rectifiers (6, 12 and 18 pulses).

Blutrafos seeks to be among the best in Brazil, providing customized and integrated solutions in electrical equipment, which can satisfy our customers needs. A highly qualified team you can count for your project.

v 2.0